Despite the vast range of cupboard sizes available today, retailers like Ikea, Argos and B&Q don’t always stock the size and shape you need.

If you’re struggling to find a cupboard that fits your requirements, consider building one from scratch.

In this step-by-step DIY guide, I show you how to build a cupboard in 6 easy steps using a project I recently undertook as an example. The cupboard houses a hot water cylinder, a washing machine, and a tumble dryer in the corner of a utility room.

Tools & Materials

Tools:

- Adjustable square

- Pencil

- 600mm spirit level

- 35mm hinge boring bit

- Electric planer or jack plane

- Combi Drill with wood and masonry bits

- Box knife

Materials:

- Timber for the frame: 63 x 38 x 2,400mm CLS

- Doors: 18mm melamine-faced chipboard

- Cladding: 9.5mm square-edged plasterboard

- A box of 25mm plasterboard screws

- Assorted wood screws, length to suit

- Rawlplugs to match the screws

- Wood glue (optional)

- Door hinges: concealed type, sprung

How to Build a Cupboard — Step-by-Step Instructions

Step 1: The Design Stage

The most crucial stage. First, you must decide what size you want. What’s the purpose of the cupboard? What will it house?

Then think about how your cupboard will look. What style of doors do you want? Will the sides be exposed? Do you need to match any other piece of furniture in the room?

Sketching may not be your strong point, but getting your idea down on paper is essential, if only to work out the materials you’ll need.

In this guide, I will show you how to build a floor-mounted cupboard using a timber frame with melamine-faced chipboard doors and plasterboard side cladding. I’m going to leave part of the frame exposed, so we’ll use decent-quality planed timber as the frame.

Step 2: Check Your Room is Square

If you’re fixing a carcass to the wall, you must ensure the walls are square and plumb. If they’re not, you’ll have to make adjustments, such as packing out or leaving a gap to fill later.

Our guide, How to Lay Quarry Tiles, explains how to check for squareness in a room, and a long spirit level will show you if the wall is plumb.

It’s essential to check for plumbness because we’re going to fix the frame to the wall, and if it leans in or out, it will affect how you hang the doors. You may have to scribe the timber frame or side panel if a wall is out of plumb.

Step 3: Build the Frame

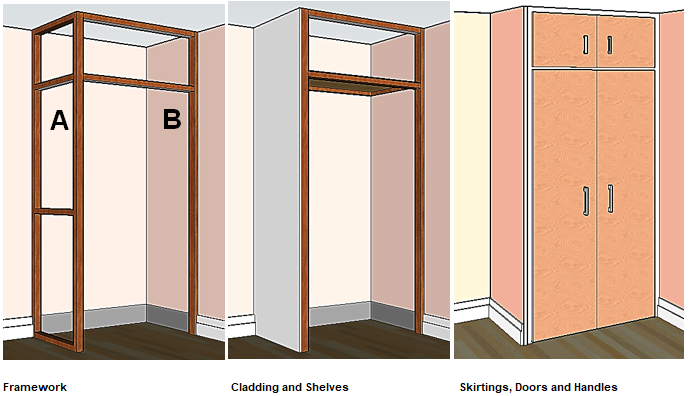

There are two ways to build the frame – prefabricate it in a workshop or on the floor (A), or make it in situ using individual wood pieces cut to size (B). Our article on stick timber explains the pros and cons of each in more detail.

In this guide, we’re going to use both methods – the side panel will be a “ladder frame”, which can be put together on the floor and then fixed to the wall. The front section, to which the doors are fixed, will be built using loose timber.

Because the cupboard I’m building will house a hot water cylinder, there’s likely to be water spillage at some point. Therefore, I won’t be fixing a bottom rail to the floor. You may prefer a bottom rail if you want to fit skirting boards and keep the doors clear of the floor.

- Carefully remove the section of skirting that will be inside the cupboard – you will need this later. An oscillating saw is ideal for this purpose.

- Build the ladder frame (A) using 63 x 38 CLS timber. Determine the size to suit your cupboard. Mine was approximately 2.4m floor to ceiling and 600mm x 1200mm on plan. This size is good because most panels for the side and doors come in 600mm increments.

- Mark on the walls where you want to fix the frame. Use a spirit level (the longer, the better) to get a perfectly plumb line.

- Use the spirit level to check for any hollows in the wall or any projections that will throw out the framing.

- When fixing the side post (B), you may have to scribe it first (see below). Fix the side post by drilling pilot holes through the post and into the wall. These holes mark the screw positions. Drill into the wall in these locations and insert Rawl plugs before screwing in the timber. If you want to hide the screw heads from view, countersink or counterbore your fixings and use filler to cover the holes.

- Before you fix the ladder frame, use a spirit level and adjustable square to ensure it is square and plumb. The post to which the door is fixed must be plumb in both directions. Also, check the measurement along the floor to the post (B) you fixed previously.

- Fix the ladder frame to the wall and ceiling. You don’t have to scribe the ladder frame because plasterboard hides it, but you must fix the doors to a perfectly plumb and square frame.

- Finally, fix the horizontal pieces to complete the frame.

Pro Tip: If you need help with scribing, the video below by Charlie DIYte describes everything you need to know.

You will notice I haven’t specified how to join the timbers for the frame – this is entirely up to you. You can use butt joints, rebate (or rabbet) joints or mitre joints – for more on this, see our article on Mitre Joints Advantages and Disadvantages.

You can also use knock-down fittings to join the pieces. These fittings are the small plastic brackets favoured by flat-packers. Note: only use these fittings for hidden joints.

Pro Tip: Before securing your cupboard to a wall, check for pipes and cables before drilling. For more information on safe drilling, watch this video by Bosch DIY.

Step 4: Attach the Cladding

Again, this is down to personal choice, and it depends on whether you want your cupboard to blend in with the walls or a kitchen unit.

For kitchen units, 18mm melamine-faced chipboard is popular because of its cost, durability and appearance. These panels usually come faced on both sides and on two edges, so you can cut to whatever size you want. Note: Using a hot iron, you can apply edging strips to exposed edges.

18mm MDF board is typical for situations where the finish isn’t important or when you want to apply your desired finish.

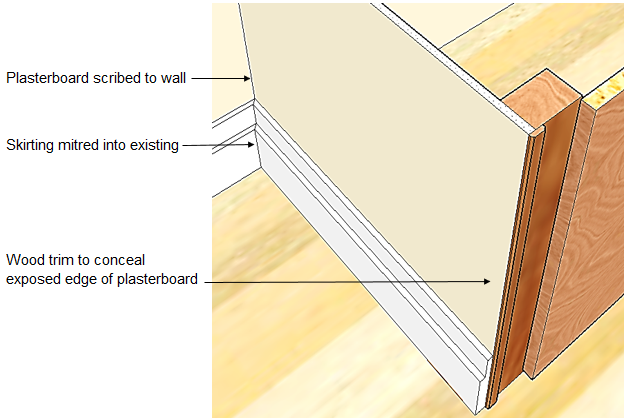

As we’re building our cupboard into a corner, and I want the side panel to blend in with the walls, I’m going to use plasterboard. B&Q’s Handiboard is good because it’s easy to handle and load into most cars. You simply score with a box knife and snap to cut the plasterboard to size.

Note: If you’re using plasterboard for the side panel, you may need to scribe it to the shape of the wall. Marking the board is done the same way Charlie DIYte describes for the frame, but cutting to shape is best done using a box knife.

Fix the plasterboard to the frame with the square edge flush with the front face of the frame. Plasterboard screws are designed specifically for this job because they easily bite into the wood without pre-drilling. You can then use filler to cover the sunken head before painting.

When it comes to fitting the skirting, you will have to cut a mitre joint against the old skirting. Our guide on How To Cut Skirting Board Without a Mitre Saw shows you exactly how to do this.

Step 5: Hang Doors and Attach Door Furniture

I used an 18mm melamine-faced chipboard for the doors because they come in the sizes I wanted – 600mm wide x 2m long.

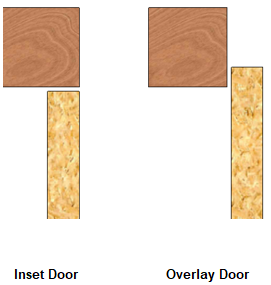

The hinge choice depends on the door type and how you will hang it. The two methods of hanging are inset and overlay.

The inset style requires greater accuracy in the door’s fitting and much more work if the frame isn’t square. For this reason, I chose the overlay style for my cupboard doors.

Hinges

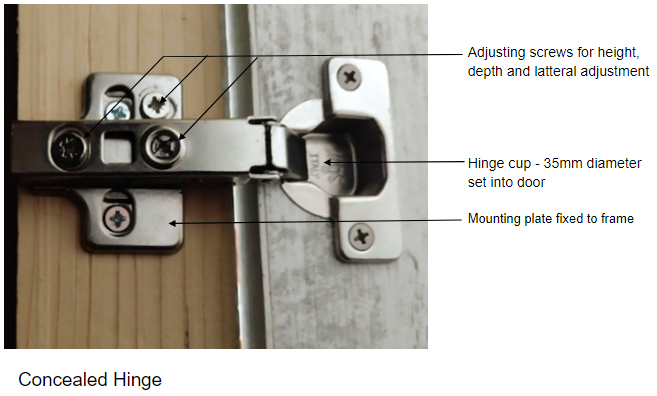

Concealed hinges are the best because they have a soft close function and are completely hidden from view when you shut the door. They don’t need latches because they hold the door tight against the frame.

You’ll need a 35mm hinge cutter and 3.5mm x 20mm wood screws (length depends on the thickness of the door).

A drill press ensures the drill is vertical and accurately sets the hole depth. Without a drill press, you’ll need a steady hand and be careful not to drill too deep.

Pro Tip: When drilling without a drill press, only drill in short bursts and at a low speed.

Here’s what you need to do:

- Use a bradawl to accurately mark the centre point of the screws for the mounting plate and hinge.

- Ensure the hinge snugly fits flush in the hole, and screw in place when everything fits nicely.

- Fix the mounting plates to the frame or carcass, and then click on the hinges

Pro Tip: To get the hang of it, do a mock-up before drilling into your door using off-cuts of the materials you will be using.

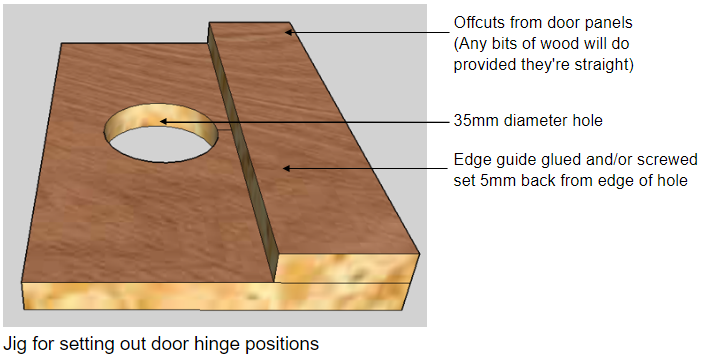

Making and using a jig is a good idea because this ensures you’re cutting each hole in the correct position. This video by Charlie DIYte shows you how to do this. The edge of the 35mm hole should be 5mm from the edge of the door, and this jig will ensure accurate drilling for each one.

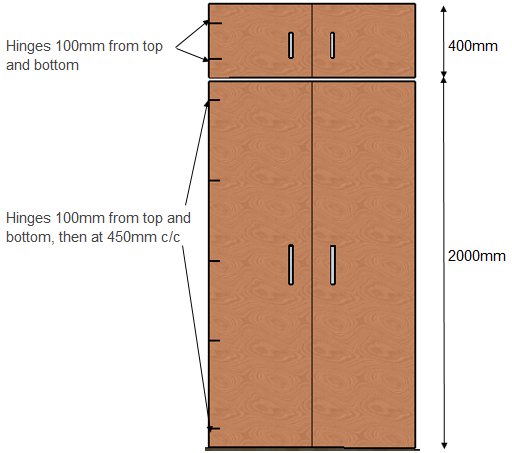

The number of hinges depends on the door size, but placing one hinge 100mm from the top and bottom and then at 450mm centres in between will work fine. So, if the door is 2m long, you will need 5 hinges (see example below).

Door Handles

This part is easy, but you must consider several aesthetics and functional options.

You want the handles to look nice but also to be practical. The choice is easy if you have something in the room that you want to match up to, such as a kitchen unit. Otherwise, think about who will use the cupboard and how they will open the doors.

Pull handles are usually fixed vertically on doors, making them easy to open with one finger if your hands are full. Knobs may be slightly more difficult on larger doors.

It’s best not to fix a handle too close to the edge as you could risk trapping your fingers – about 100mm in from the edge of the door is ideal.

Stainless steel and anodised or brushed aluminium are easy to clean, whereas polished chrome or brass will show finger marks.

Step 6: Fix the Shelves

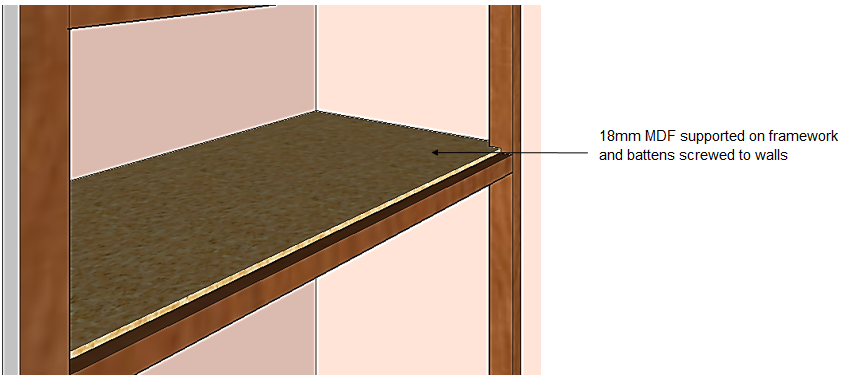

In carcass construction, you can support shelving on plastic supports. For purpose-built framed cupboards, there is a much wider choice. You can use the framing members as part of the support with timber battens fixed to the walls for the other edges.

Or you can use a fully adjustable system such as this one by Urba Boxx.

Or any type of fixed bracket screwed into the walls.

How to Build a Cupboard – Final Thoughts

This guide shows you how to build a full-height cupboard, but the same principles apply to a much smaller base or wall unit.

Pro Tip: You don’t have to go for plain flush doors. This video by Charlie DIYte shows you how to make panelled doors easily from sheets of MDF board.

For more carpentry guides like this, check out our guides to boxing in pipes and boilers.