Use knock-down fittings if you want an easy life when joining two pieces of wood. They’re the simplest joinery method, widely used in everything from flat-pack furniture to kitchen units.

Knock-down fittings have become my go-to solution over many years of DIY projects, especially when I’m against the clock.

Knock-Down Fittings Basics

Knock-down fittings are a carpentry novice’s best friend. They’re a bracket that joins two pieces of wood using a screwdriver, drill, or other essential tools. They require no skill and enable you to assemble and disassemble furniture easily, hence why flat-pack sellers love them.

Knock-down fittings are also ideal when securing tricky sheet material like chipboard and composite board used in everyday construction. So, if you’re building a cupboard or boxing in pipework, you’ll need knock-down fittings.

Knock-Down Fittings — The Top 7 Types

There are several varieties of knock-down fittings, each with its own merits. They can be brackets, plates, plastic, wood, and even locking nuts. Let’s take a look at the choices available.

1. Plastic Block Fitting

A plastic block is rectangular with screw holes pre-drilled on two sides. Press it against the first sheet of material, insert the screws and then repeat the process with the other sheet.

You commonly find Plastic knock-down fittings in kitchens, wardrobes, and other mass-produced furniture inside your home. They’re cheap to make, inexpensive, and easy to use.

Pro Tip: Make light work of screws by investing in an electric screwdriver. It saves you time and effort and helps to relieve wrist fatigue.

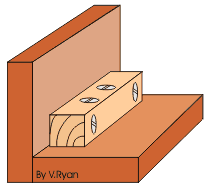

2. Square Section Batten

Instead of plastic, manufacturers sometimes use wood. Pine is particularly popular because it’s easy to work with and cheap. It has all the qualities of plastic blocks, but unlike plastic blocks, you can make them yourself from wood offcuts.

I’ve lost count of the number of times I’ve knocked up a workbench or sawhorse using wooden square section battens from old bits of wood.

3. Two-Block Joints

Some in the trade refer to two-block joints as lok-joints because they consist of two pieces of plastic with a screw through the middle. As you tighten the screw, it threads into the second plastic block, drawing two pins together and locking the wood.

They’re made of plastic, readily available in DIY stores, and anyone can use them. This joint enables you to assemble and disassemble furniture without damaging the wood panelling because you turn the central screw in the plastic block. Thanks to the pins, it also keeps the fitting straight, creating a solid joint.

4. Rigid Joint

Rigid joints are typically triangular with a 90-degree plate that butts against both wooden panels. They’re made of plastic with screw holes in both faces to secure the structure.

The rigid joint is exceptionally robust, holding the wood together no matter what punishment it gets.

Like the other plastic fittings, you can pick up rigid joints online and from local DIY stores.

5. Scan Joints

Scan joints are less common, but it’s the best choice for a strong connection. It consists of a cylinder inserted into one side of the cabinet in a pre-drilled hole.

The other element is a long screw that gets pushed through a hole in the second wood section. It threads through the cylinder, tightening both panels as you twist the screwdriver or Allen key.

These knock-down fittings have several names. You may know them as barrel nuts or cross dowels. They may also differ slightly in design, but the principle remains the same: a long bolt threaded into a female locking nut.

Scan joints typically come in two parts, with the barrel nut sold separately to the bolt, which makes them more expensive than other knock-down fittings.

6. Cam Lock Fitting

Cam lock fittings are another favourite with flat-pack furniture manufacturers. A cam lock is a small disk with a grooved cross in the face. It slots into a pre-drilled hole in one panel, while a specially shaped screw is attached to the second panel.

The screw inserts into the side of the first board, and when you twist the cam lock, it rotates to lock the screw in place, clamping both sections.

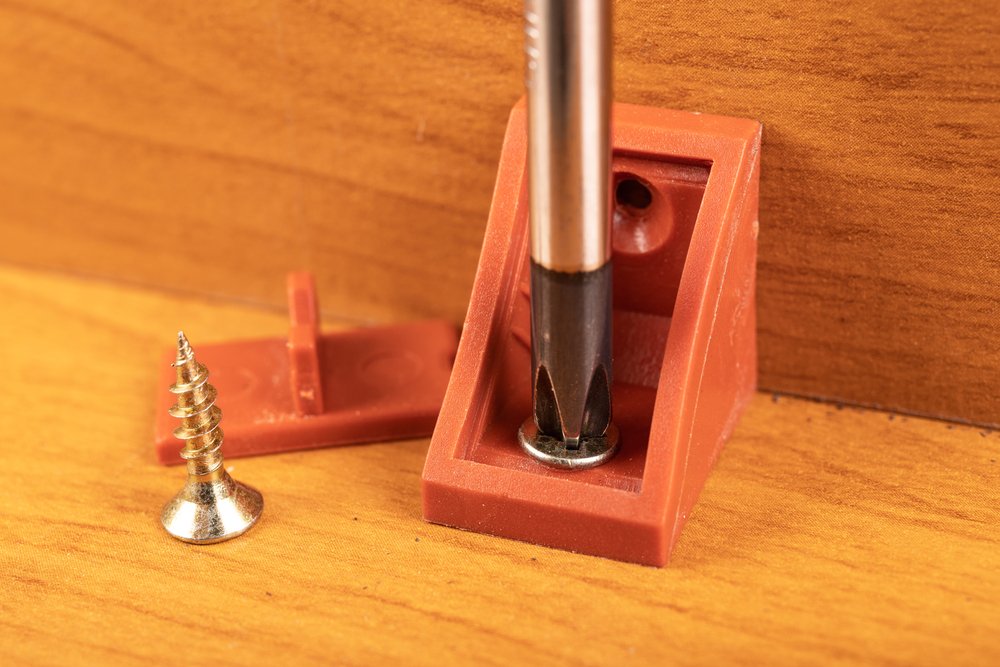

7. Confirmat Screws

Confirmat screws drive directly into panels thanks to their extended tapered shaft. The specially designed cutting threads ensure the connection between right-angled sections is accurate and robust.

These screws typically have a hex-shaped head which tightens with an Allen key.

Check out the video below for more information on knock-down fittings and flat-pack furniture.

Final Thoughts

Knock-down fittings are the simplest means of securing two panels together. They require zero carpentry or joinery skills and just a few essential tools.

They may not be pretty, but their functional properties make them very popular with many flat-pack furniture manufacturers.