Lap joints are commonly used in metalwork, woodworking, and plastic piping. It’s one of the most accessible joints to create, which I found to my advantage during my house renovation. However, is it the be-all and end-all for your upcoming project?

I decided to focus on lap joint advantages and disadvantages to give you the definitive answer.

What Is a Lap Joint?

A lap joint overlaps the corresponding piece to form a clean joint that can be glued, welded, or brazed.

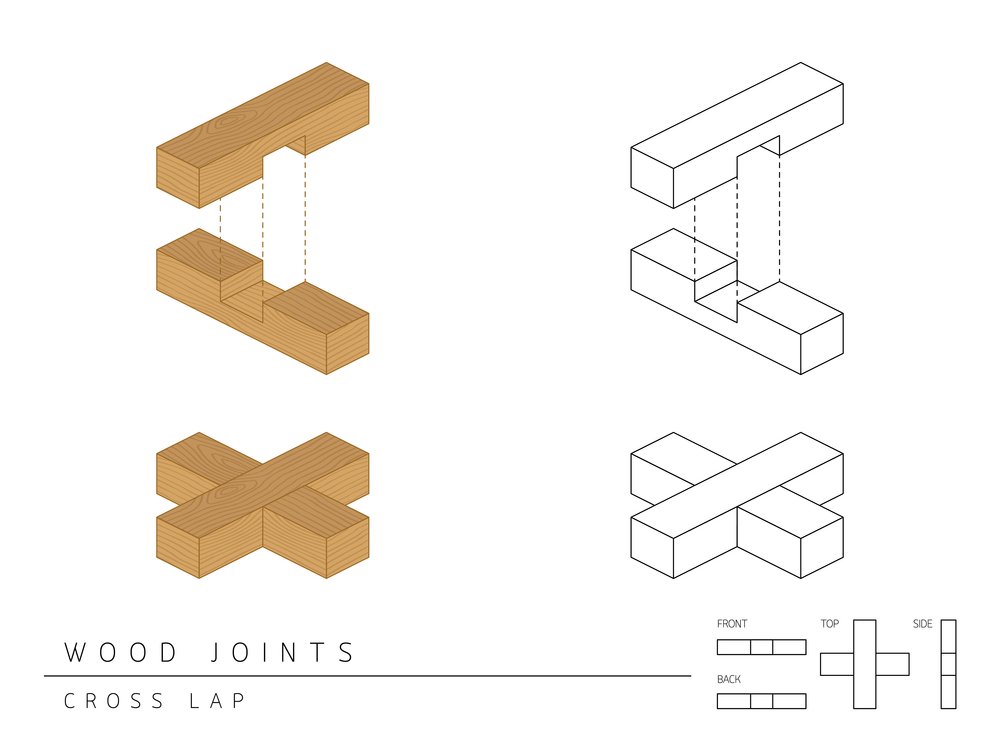

You start by cutting a rabbet so both pieces sit flush, creating a “lap.” This YouTube video demonstrates how to cut a simple cross-lap joint.

Lap joints are sturdy and great for everything from garden furniture to log cabins. They’re good at resisting tension forces because one piece bears the weight of the other, reducing twisting, warping, and splitting.

Essentially, there are four styles of lap joint:

- Half-lap

- Mitred half-lap

- Cross-lap

- Dovetail crossed-lap

Lap Joint Advantages and Disadvantages

So, your next project is about to start, and you still can’t decide if lap joints are the way to go. Let’s look at the pros and cons in more detail.

Advantages

Let’s deal with a lap joint’s positive aspects and highlight the reasons for using it.

Rigidity

Lap joints are easy to create and glue together, providing a stable connection. The advantage is you don’t have to cut against the grain, unlike dovetail or mortise & tenon joints.

Easy to Assemble

Unlike a butt joint (which has twice the number of sides), a lap joint makes constructing your project much faster. It’s also better for joining two pieces of wood at 90 degrees.

Easy to Dismantle

The flip side of the easy assembly is simple disassembly (provided you can break the glue). You can take your project apart in double-quick time. Trust me; this is a huge advantage when relocating a garden building!

Accommodates Different Material Thicknesses

When welding, joining two pieces of metal with different thicknesses can be tricky. A lap joint makes it possible, but you must remember to weld the thinnest piece on top or risk your project buckling.

Versatility

A lap joint is your new best friend if your next project involves making boxes, flat frames, tables, and other furniture.

During my home renovation project, I found them helpful in building structures when boxing in my boiler and concealing pipework.

Ideal for Beginners

Sure, there are more complex joints, and that’s fine for the more experienced, but cutting a lap joint is a great way to learn when you’re new to carpentry. Furthermore, you only need standard tools, like chisels, saws, and hammers.

Lap joints are so easy to make; it’s the reason why they have been dubbed “beginner-friendly.”

Clean Finish

Some joints, like a mitre joint, are used to showcase the carpenter’s skill, but not so with a lap joint.

While it may lack the sophistication of other joints, a lap joint requires no special treatments or finishes to look good. It leaves a simple and clean line, which is also easy to conceal.

Disadvantages

We’ve dealt with the good; now it’s the turn of the bad. Why should you think twice about using a lap joint? Let’s take a look:

Gaps In Joints

Lap joints may be simple, but they’re a bit crude for some projects.

Due to how the joint gets cut, they can leave small gaps between each board. These gaps might allow some movement, which is terrible news for garden structures like sheds and cabins.

It doesn’t matter much on indoor projects because you can conceal the gaps with filler and paint.

Doesn’t Hold Glue Well

Think again if you’re just glueing your lap joint and hoping for the best. Lap joints are inferior at holding glue and adhering to the other piece of material. You will need clamps to hold them together while the adhesive dries.

Not Ideal for Large Projects

Using such thin pieces to make contact can cause issues of cracking and splitting when constructing more extensive, cumbersome projects. Ensure that you leave minimal gaps between the boards and the glue is completely set.

Pro Tip: There are far better joints offering more tensile strength. A mortise & tenon joint springs to mind.

Not Aesthetically Pleasing

We’ve touched on the simplicity of lap joints and that they can look neat when done well. However, they’re not the most aesthetically pleasing. For this reason, most builders only use a lap joint where the joint is concealed.

Final Thoughts

So, there you have it, the definitive guide to lap joint advantages and disadvantages.

Remember, if you decide to use a lap joint in your next project, ensure that you clamp it while the glue sets.

Also, if you want to build a large structure in the garden, use lap joints for concealed areas and more robust alternatives like dovetail joints for parts taking the strain.

If carpentry is beyond you, or you’re short on time, you can always find a highly-rated professional in your local areas using Rated People.

FAQ

Below are answers to frequently asked questions about wood joints.

What are the advantages of a half-lap joint?

Half-lap joints are easy to make and provide strong joints when building cabinets or framing. Furthermore, they offer an excellent long-grain glueing surface, which helps tackle distortion.

What are the advantages of wood joints?

Some wood joints are incredibly robust, while others are easy to make and fast to construct.

Dovetail joints are excellent for showing off the carpenter’s skill and providing a strong joint, while lap joints are easy to make but are less attractive.

What are the advantages and disadvantages of a housing joint?

The main advantage of a housing joint is its strength and simplicity. Housing joints are typically found in the backs of drawers and provide stability from all directions.

The disadvantage of a housing joint is its ugly appearance. Also, it breaks under sustained pressure, so it’s unsuitable for heavy loads.