With rising energy costs, the need for better insulation and reduced heat loss has never been greater, but this creates another problem — damp!

As an architectural technologist, one of the most significant issues in house building is dampness and moisture control. Rising damp and condensation result from poor control measures and must be tackled at the design stage by adding vapour barriers and damp-proof membranes into the plans.

So, what is a vapour barrier, and how does it differ from a damp-proof membrane?

Vapour Barrier vs Damp Proof Membrane

Builders use damp-proof membranes (DPM) primarily under concrete slabs to prevent moisture ingress by capillary action. In contrast, a vapour barrier (VB) is fitted on the warm side of walls or roofs to stop interstitial condensation.

Let’s take a look at how these membranes function.

What is a Vapour Barrier (VB)?

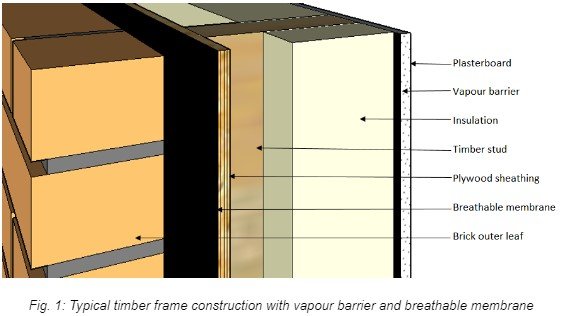

Builders primarily use VBs in timber frame construction, where it’s essential to stop moist air from passing through into the insulation, where it will condense when it hits a cold spot — a phenomenon known as interstitial condensation.

VBs don’t need to be as robust as DPMs, so they’re much thinner — typically 120-micron (500 gauge) polythene sheet like this one from Damplas.

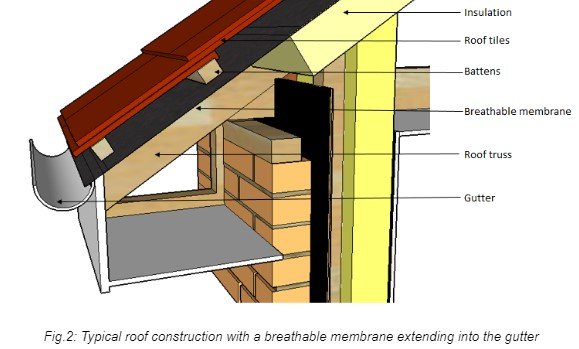

You’ll also need a VB in cold roof construction, where the roof deck or covering is above the insulation.

You can achieve the same effect using foil-backed plasterboard, but you must ensure that you seal the joints properly.

Builders also use VBs on solid floors where you must protect the floor finish from moisture in the concrete or screed. You can learn more about this in our thermal underlay buying guide.

Several liquid vapour barriers on the market can be applied by paintbrush or airless spray. The advantage of liquid barriers is that they create an excellent seal around penetrations and at wall/floor/roof junctions.

Recently, I came across Passive Purple, a VOC-free vapour control paint. You can apply it with a paintbrush or airless sprayer, and because it’s water-based, it’s easy to clean up afterwards.

What is a Damp Proof Membrane (DPM)?

A DPM prevents groundwater from being drawn into the concrete floor slab by capillary action, leading to dampness on the top surface. This damp detrimentally affects permeable finishes, such as carpet or laminate flooring.

Polyethylene is the most common material for a DPM, and the minimum thickness for use under a concrete slab is 300 microns (1200 gauge). This EcoMembrane DPM by Visqueen is among the most popular on the market.

Other Types of Membranes

You may have heard of two terms describing moisture control layers — damp-proof courses and breathable membranes.

Damp Proof Course (DPC)

DPCs are inserted into brick or block walls, usually at ground floor level and around door and window openings. They perform the same function as a DPM, preventing moisture from passing through the wall by capillary action.

Modern DPCs are made from high-density polyethylene (HDPE) or recycled polythene. Because DPCs are built into walls, they must be robust and flexible, so they’re much thicker than the other membranes.

On older properties, you’re likely to find a bitumen-based DPC. These go brittle over time, so you must replace them when this occurs. The simplest way to replace them is to inject chemicals into the wall to perform the same function of stopping the capillary action.

For more information on this, check out our damp proofing cost guide.

Breathable Membrane

Breathable membranes allow air to pass through but prevent water ingress. They’re chiefly used on tiled roofs where they direct rainwater penetrating the primary covering into the drainage system. Because they’re breathable, these membranes negate the need for ventilation in the roof space.

Pro Tip: Eurovent’s breathable membranes are highly rated and excellent for walls and roofs.

Final Thoughts

So now you know the difference between a damp-proof membrane and a vapour barrier and, more importantly, when to use each one. Think of it in terms of dampness caused by capillary action (DPM) and dampness caused by moisture-laden air (VB).

Before you go, check out our guide to damp proofing costs for advice on the different types of damp and how much surveyors charge for an inspection and report.

FAQ

Below are answers to frequently asked questions about vapour barriers and damp-proof membranes.

Can a damp-proof membrane be used as a vapour barrier?

You can use a DPM as a VB if the joints are taped. A DPM is usually much thicker than a VB (300 microns as opposed to 120 microns), so a VB is unsuitable for use as a DPM.

When should you use a damp-proof membrane?

Builders use DPMs to prevent moisture from rising through the structure via capillary action. DPMs are installed within concrete floor slabs and brick or block walls, although, in wall construction, it’s referred to as a damp proof course (DPC).

What is the main difference between DPM and DPC?

In practical terms, a DPM and DPC perform the same function — they prevent moisture from rising into masonry walls and concrete floors through capillary action. The main difference is in where you use them.

A DPM is a sheet (typically polythene) laid on sand and hardcore before pouring a concrete floor. A DPC is a strip of polyethylene, much thicker than the polythene sheet, laid horizontally or vertically in masonry walls.

When should you use a vapour barrier?

Builders always fix a vapour barrier on the warm side of any insulation to prevent moist air from entering the structure and condensing as it meets a cooler surface.

Although this usually applies to walls and roofs, you can also use a vapour barrier on a concrete floor to prevent any moisture in the concrete from affecting the floor covering.

What’s the difference between a vapour barrier and a breathable membrane?

A vapour barrier blocks moist air, whereas a breathable membrane repels water but allows air to pass.

Vapour barriers are positioned internally where the warm moisture-laden air is, and breathable membranes are situated on the cold side of a structure, below or behind the weathering layer.

Because of the difference in function, the two have different compositions. Vapour barriers are typically a single polythene sheet, whereas breathable membranes are multi-layered sheets incorporating UV radiation protection, a waterproof layer, and a microporous polypropylene film.