Despite having over 40 years of DIY experience, I only recently discovered that I sometimes use the wrong saw for my carpentry projects. To fix this, I decided to dive deep into the world of saws and their various uses.

After many hours researching and testing all the different types, I’ve whittled this list down to 21 essential saws. Some will surprise you, and some will change the way you work.

Note: I’ve split this list into two main parts — Hand Saws and Power Saws.

Table of Contents

Hand Saws

Before we go through the list of essential hand saws, let’s look at some key terms.

Rip-cutting

Cutting along the grain is known as rip-cutting, requiring a saw blade with around 10 teeth per inch (TPI). The teeth have a straight edge to chisel through the grain.

Cross-cutting

Cutting across the grain is known as cross-cutting. For this purpose, the blades have fewer teeth, and they’re angled on the inside edge to slice through fibres like tiny knives.

The more teeth a blade has, the finer the cut, meaning a cross-cut blade cuts more coarsely than a rip-cut blade. The deep trough (known as a gullet) between the teeth prevents the blade from clogging up as you cut.

Most modern saws can cut along and across the grain. Still, general-purpose saws are not the best option if you’re serious about carpentry and joinery work.

Push or Pull?

Some saws cut on the push stroke, others on the pull stroke, and some cut both ways. The direction of the teeth determines which direction a saw cuts.

If the teeth point away from the handle, the saw cuts as you push. This allows you to put more oomph into it, which is great for sawing a challenging piece of wood or working across the grain.

When the teeth point towards the handle, the saw cuts on the pull action, resulting in a more delicate cut.

Saws that cut both ways have teeth that point straight down. These saws are great for fast cutting where accuracy is not required, such as trimming branches off a tree.

The ‘set’ of the teeth is how they’re angled outwards, alternating left and right. This makes the cut wider than the blade, preventing it from sticking or binding.

Handles

There are two types of handles, the pistol grip and the straight handle.

A pistol grip is often seen on saws for medium to heavy-duty use. In contrast, the straight handle is better for lighter, detailed work.

Let’s now look at the most important hand saws and when best to use them.

1. Traditional Handsaw

There are three types of hand saws — cross-cut, rip, and combination — each defined by the number of teeth and their shape.

Keen amateurs and most professionals typically have a selection of handsaws for various uses. Still, the combination saw is the tool of choice for most DIY enthusiasts.

To help you choose the best handsaw for the job, check out the video below:

| Pros | Cons |

|---|---|

| Cuts fast with and across the grain. | It’s not particularly accurate. |

| Good in the garden and doing general carpentry. | Expect some rough edges. |

| Excellent on MDF board and laminate flooring. | It doesn’t cut through metal very well, so watch for nails. |

2. Tenon Saw

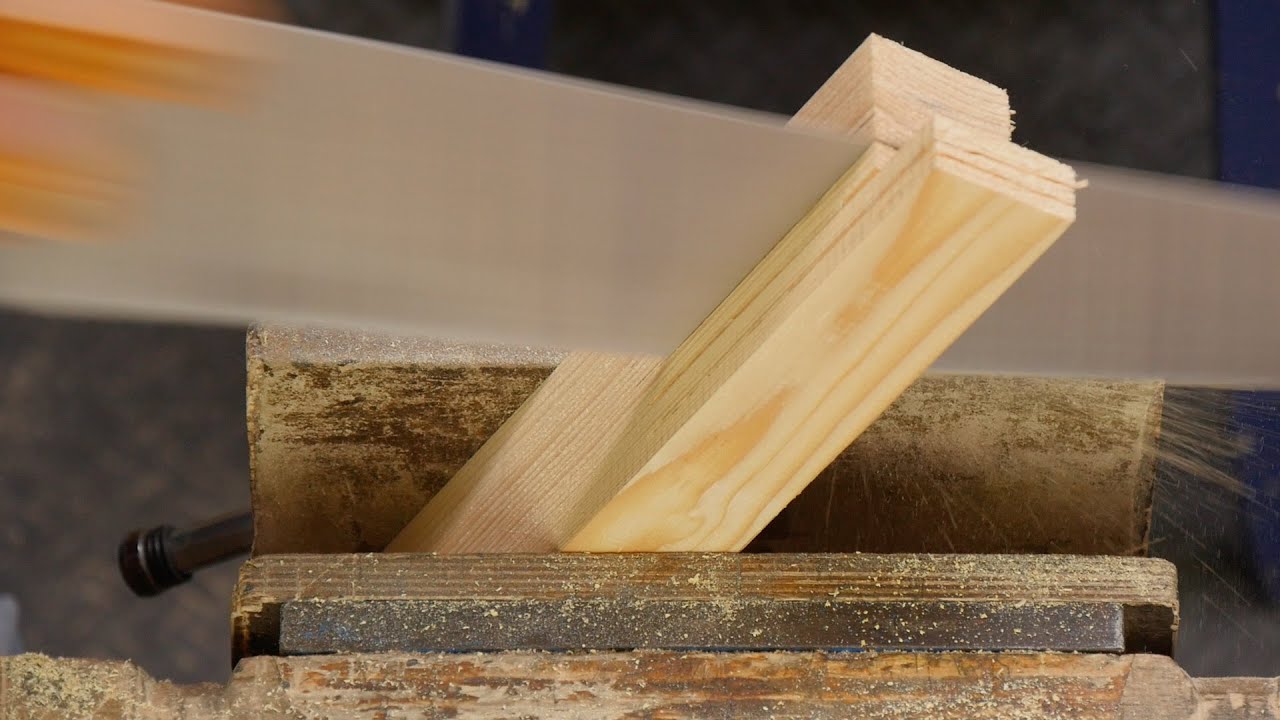

This short, stubby little saw is sometimes called a backsaw because it has a strip of metal or wood running along the spine to stiffen the blade.

Tenon saws make fine, straight cuts, which is great for forming mortise and tenon joints (hence the name). They have 10 to 14 TPI and are set to cross-cut the wood as you push.

When used with a mitre block, they’re great for forming mitred joints and right angles in wooden frames, which is why cabinet makers favour them.

There’s a shorter, straight-handled version of this saw, often called a ‘Gents Saw‘. This saw has more teeth set to rip the wood as you cut along the grain and is best used for forming dovetail joints.

| Pros | Cons |

|---|---|

| The stiff blade helps form fine accurate cuts. | It cannot cut through wood thicker than the blade depth. |

| Ideal for forming precise joints in joinery and cabinetry work. | Not very versatile. |

| Not suitable for metal. |

3. Japanese Saw

Japanese saws are characterised by a straight handle and a strong, thin cutting blade, which cuts on the pull stroke for greater accuracy.

Three popular types — dozuki, ryoba, and kataba — cover everything from cutting delicate joints to lopping branches off trees.

As with the tenon saw, the dozuki has a rigid spine, making it ideal for cutting neat joints. The blade is around 150mm long, with 20–26 TPI.

The ryoba is double-edged, with one edge for cross-cutting and the other for ripping. The 240mm blade has 9 TPI on one edge and 26 TPI on the other. This saw is very flexible and can cut close to the surface.

The kataba has a single cutting edge with no spine. It’s a cross-cut saw with around 15 TPI and has the longest blade at 270mm. This makes the kataba ideal for cutting branches off trees.

If you’re a keen woodworker, these are great saws to own, especially genuine Japanese imports. They’re traditional tools, but you can use them on many modern materials.

| Pros | Cons |

|---|---|

| Capable of cutting fine, accurate cuts for joints and for cutting through tough hardwoods. | You need all three types to cover most situations. |

| The ryoba style is excellent for both fine rip-cuts and quick cross-cuts. | Forming a perfectly straight rip-cut on both sides takes plenty of practice. |

| Blades can cut through non-ferrous metal. |

4. Bow Saw

A bow saw is a type of cross-cut saw that is more at home in the garden. The long blade, which has between 3 and 8 TPI, is set to cut during the push and pull strokes, making it ideal for cutting thick branches quickly.

The blade is tensioned across a tubular steel frame incorporating a closed pistol-grip handle for hand protection.

There are two types of blades — one for cutting wet or green wood (raker tooth) and one for dry timber (peg tooth). These two blades are quickly interchangeable.

| Pros | Cons |

|---|---|

| Cuts fast across the grain. | Produces rough edges. |

| Ideal for cutting thick branches off trees. | Limited use in the home. |

| Blades are quickly Interchangeable for different types of wood. |

5. Hacksaw

The hacksaw is my favourite saw because it’s incredibly versatile and quickly cuts through wood, plastic and most metals. It’s also easy to change blades, so you always have a sharp cutting edge.

Furthermore, its thin blade and rigid frame make cutting through pipes, tubing, and small wood sections easy, but it’s not so good on thicker materials.

Hacksaws usually come with a blade set in a wavy line, which is good for thin metal sheets but not for thick pieces of wood as it tends to bind. Other blades are available for more rigid metals and plastic but not timber.

The hacksaw is designed to cut on the push stroke, allowing you to apply more force when cutting challenging materials. And with up to 32 TPI, the hacksaw can produce a neat cut.

Pro Tip: When changing the blade, ensure the teeth point away from the handle unless you want to cut on the pull stroke.

| Pros | Cons |

|---|---|

| Interchangeable blades for different materials. | The shape of the frame and handle makes it difficult to cut tight curves. |

| Ideal for plastic and metal pipes. | Not suitable for thick pieces of wood such as tree branches. |

| Extremely versatile. |

6. Coping Saw

The coping saw is used for delicate work, and its blade can rotate, making it easier to cut in tight spots.

It gets its name from the type of joint it was designed for, a coped joint, which is a ‘scribed joint’ in the corners of moulded skirting or coving. Its thin blade cuts on the pull stroke and typically has up to 20 TPI.

Coping saws are also handy for forming shaped cut-outs in wood, plastic, ceramic and non-ferrous metal, but you need the right blade to suit the material. Fortunately, the blades are inexpensive and easy to change.

| Pros | Cons |

|---|---|

| Interchangeable blades for different materials. | Not suitable for heavy-duty cutting. |

| Ideal for cutting mitres in moulded trim. | Limited use. |

| The small rotating blade makes it easy to cut curves. | |

| Produces an elegant finish. |

7. Fret Saw

A fret saw looks very similar to a coping saw but has a much deeper and narrower U-shaped frame. This deeper frame allows it to reach places a coping saw can’t touch.

The thin interchangeable blades have up to 48 TPI, and like the coping saw, it cuts on the pull stroke. However, unlike the coping saw, the blade is fixed, so cutting intricate shapes is difficult.

| Pros | Cons |

|---|---|

| Interchangeable blades for different materials. | Blades are easily broken. |

| Favoured by model makers. | Fixed blade. |

| The thin, flexible blade makes fine cuts much easier. | |

| Produces an elegant finish. | |

| The deeper frame allows you to go further into the wood. |

8. Keyhole Saw

Also known as a compass saw, the keyhole saw has an open pistol grip or straight handle. It’s great at quickly cutting shapes in drywall and is equally effective on wood panelling.

The blades have 7 to 10 TPI, and the teeth are set to cut on the push stroke.

Due to their size, keyhole saws are useful for working in tight spaces. However, the finish is not the neatest due to its relatively low TPI.

| Pros | Cons |

|---|---|

| Good in tight spaces. | Creates rough edges. |

| Quick and easy to use. | Not suitable for large cuts. |

9. Hole Saw

Some would class this as a drill bit because it attaches to your drill. However, flat spade drill bits only cut holes in wood up to 32mm in diameter, whereas hole saws cut up to 127mm in diameter across a range of materials.

If you want to cut a hole in ceramic tiles, use a diamond-edged hole saw attached to a drill. While cutting, wet the teeth to reduce friction and keep the cutting edge cool. For more info, check out this video.

Pro Tip: lightly lubricate the inner surface of the hole saw so it’s easier to remove cut materials. DON’T use WD-40 as this goes everywhere, including the cutting edge.

| Pros | Cons |

|---|---|

| It cuts large holes in a variety of materials. | Hole saw depth limits cutting depth. |

| Diamond-edged saws are great for glass and ceramics. | Removing the cut material from the saw’s centre can be challenging (see pro tip above). |

| Central arbour drill bit ensures accuracy on wood. |

Power Saws

Although hand saws are capable of most jobs, power saws cut quicker with less effort, and depending on your skill level, they often cut more accurately.

However, this convenience comes at a painful price if you’re not careful when operating these dangerous machines. So before we go through the list of essential power saws, let’s consider health & safety.

Safety Measures

The raw power and speed of power tools make nasty accidents far more likely when compared with manual tools.

There are two aspects of safety — preventive measures and protective measures.

Always look at preventive measures first and personal protection second. This means using tools correctly, having securely fitted guards, clearing the floor of trip hazards, and keeping others out of the way, especially children and pets.

Pro Tip: Hand-held power saws are prone to kickback, so always be prepared to release the trigger when you feel the saw begin to bind.

Always wear appropriate personal protective equipment (PPE). Excessive PPE can hinder your movements and potentially increase the risk rather than mitigate it. Choose PPE that protects you from the hazards you can’t avoid, such as eye protection, gloves, ear defenders, face masks and steel top cap boots.

Pro Tip: Plenty of dust is created when cutting wood, so use an extraction system where possible.

Corded or Cordless

Many of the power tools listed below can be battery-powered (DC) or mains-powered (AC), and there are pros & cons to each power source. For example, you can use a cordless chainsaw outside without being near a power socket. However, chopping down big trees quickly drains the battery, so you need a spare battery on charge.

Pro Tip: Many power tool manufacturers offer body-only power tools with no battery. This can save you money if you already own compatible batteries for other power tools in the same product range.

Mains-powered tools are typically more powerful and don’t suffer from power loss unless the grid goes down. They’re also lighter because they don’t have a heavy battery weighing them down.

In my experience, it’s better to have a mix of corded and cordless tools, but it depends on how you use them. The choice between the two is often a trade-off between power and portability. Other factors like cost, safety and convenience also play a part in the decision-making process.

Moving on…

Continuing with our list of 21 saws, I’ve split power saws into two groups — table or floor-mounted saws and hand-held saws.

10. Table Saw

The table saw is a must-have power tool for all joinery and carpentry work. It consists of a flat table with a high-speed motor underneath that powers a changeable circular blade.

It operates similarly to a circular saw. However, you offer the material (wood, chipboard, MDF, sheet metal) to the blade, pushing it across the flat surface. This motion gives you greater control over the cut and a more precise finish.

Table saws can perform bevelled and mitred cuts, and there are different blades to suit various materials, making this a handy and versatile tool.

To learn more, check out our table saw buying guide.

| Pros | Cons |

|---|---|

| Great for rip cuts and repetitive work. | It can be very noisy. |

| Versatile — cuts various materials at almost any angle. | Max cutting thickness is limited to around 85mm when vertical. |

| Cuts wide panels as well as narrow planks. | Not the most accurate tool. |

11. Mitre Saw

Mitre saws are ideal for precision cutting at adjustable angles, as you can set them to cut any angle horizontally and up to 45° vertically. I highly recommend using them for mitred joints on skirting boards and architraves.

The blade is mounted on a swing arm, which you bring down onto your workpiece. You can clamp longer pieces to the frame, keeping your free hand safely out of the way. Furthermore, the swing arm has a guard to protect your hand until the blade is just above the workpiece.

Note: Most mitre saws, especially the good ones, come fitted with a laser for accurate cutting.

| Pros | Cons |

|---|---|

| Produces precise cuts at almost any angle. | Not suitable for rip-cutting. |

| Capable of 3-dimensional compound cuts. | Max cutting thickness is limited to around 70–85mm. |

12. Bandsaw

The bandsaw is a must-have machine if you do lots of repetitive, continuous cutting.

It works by driving a steel band over two wheels above and below the workbench in a continuous loop. This band contains teeth that cut the material in only one direction, making it more efficient than a scroll saw, which works reciprocally.

Bandsaws support a wide range of thicknesses (80–150mm), and you can tilt the table up to 45° for mitred and bevelled cuts.

Some bandsaws are floor-mounted, while others are designed to be fixed onto a worktop. There are also handheld models like the one below from Milwaukee Tools.

This handheld version is mainly used for plumbing and metalwork. However, as similar and lighter options are available, it’s probably one tool you can do without.

| Pros | Cons |

|---|---|

| Great for repetitive cutting. | The stationary type is heavy and bulky. |

| Capable of cutting thicker pieces than a table saw. | The portable type is too big for a tool that only cuts small pieces. |

13. Electric Tile Saw

Electric tile saws use a cutting disk with a diamond particle-coated edge, similar to an angle grinder. The water reservoir below the table keeps the cutting edge cool and reduces dust.

These saws include sliding guides on each side of the cutting disk, allowing you to make accurate and repetitive cuts.

Pro Tip: Place the tile on the table face up, preventing the ceramic face from chipping as you cut.

To learn more, check out our electric tile cutter reviews.

| Pros | Cons |

|---|---|

| Cuts ceramic and porcelain tiles effortlessly. | Noisy, especially in an enclosed space. |

| It can cut glass with a change of blade. | Tiles can chip if the blade is worn. |

| Easy to cut shapes. |

14. Scroll Saw

Scroll saws cut precise shapes in wood or metal using a thin blade that moves up and down at varying speeds. They’re typically used by hobbyists for smaller intricate jobs.

Some models include a foot pedal that controls the speed and stops the motor without taking your hands off the workpiece.

Pro Tip: You can tilt the table up to 45° for bevel cuts. However, when you do this, the maximum thickness of the material is more than halved.

To learn more, check out our scroll saw buying guide.

| Pros | Cons |

|---|---|

| Creates tight, precise curves and accurate straight cuts. | Max cutting thickness is limited to around 20mm on bevel cuts. |

| Easy to use if it includes a foot pedal. |

15. Circular Saw

A circular saw is a versatile tool and is essential for decking projects. They’re also great for cutting timber frames, floor & ceiling joists, rafters and cladding materials.

These saws can cross-cut and rip-cut various materials at adjustable cutting depths. Furthermore, if it includes an adjustable base plate (as many do), you can make angled cuts up to 60 degrees.

There are blades to suit most materials (i.e. wood, metal, stone, and ceramics), so always use the right circular saw blade to avoid damaging it.

If you’re still not convinced you need a circular saw, check out the video below:

| Pros | Cons |

|---|---|

| Versatile — cuts through plywood, MDF, softwood and hardwood. It also cuts metal, stone and ceramics. | Not suitable for fine, precise work. |

| Suitable for cross cuts, rip cuts, bevel cuts and grooves. | |

| Portable |

16. Jigsaw

Jigsaws use a thin reciprocating blade to make straight and curved cuts in most sheet materials, including wood boards and panels.

This handy tool uses interchangeable jigsaw blades designed for each material, and they’re often used to scribe wood flooring around architraves.

Pro Tip: Go for a cordless model, as the cord always seems to get in the way, even when cutting long straight lines.

To learn more, check out our jigsaw buying guide.

| Pros | Cons |

|---|---|

| A handy tool for cutting wood boards and panels. | Not suitable for thick wooden sections. |

| Capable of cutting metal with a simple change of blade. | Hard to make accurate straight cuts. |

17. Reciprocating Saw

If you’re undertaking demolition work or want to quickly cut through large wood sections, this tool is for you.

The reciprocating saw uses a push-pull action that is similar to a jigsaw. However, the blades are more prolonged, allowing you to easily cut through 180mm thick wooden posts and beams.

Most models support toolless blade changes, so you can quickly switch to a metal cutting blade for wrought iron railings and the like.

With the centre of gravity so far from the handle, even the lightest models need two hands to operate. Compact models are easier to use but are not as powerful.

| Pros | Cons |

|---|---|

| Cuts through thick wood sections up to 180mm. | You need two hands to operate most models. |

| It cuts through metal, so perfect for general heavy-duty work. | Noise and vibration issues with cheaper models. |

18. Oscillating Saw

The Oscillating saw works similarly to an electric razor, with the teeth oscillating from side to side.

The cutting blade is shaped to reach tight spots against the floor or an adjoining wall, and you can use it to cut through wallboard, tiles, and sheet metal.

This multi-purpose saw is also useful for removing grout, cutting through nails and doing other small jobs around the house.

Furthermore, some models come with grinding and sanding attachments, making it a handy multi-tool for DIY enthusiasts and professionals.

| Pros | Cons |

|---|---|

| Works in tight corners. | Not suitable for cutting long runs. |

| Cuts through wood, plastic and metal. Added accessories make it a handy multi-tool. |

19. Plunge Saw

Also referred to as a track saw, this version of a circular saw runs along a track placed over the cut line.

Plunge saws differ from circular saws in that the blade is set within the machine, negating the need for a retractable guard. This feature makes plunge saws much safer to use.

This saw is highly valued amongst kitchen fitters because it can ‘plunge’ the blade into 38mm and 50mm thick worktops, making it easy to form sink cutouts.

To learn more, check out our plunge saw buying guide.

| Pros | Cons |

|---|---|

| Lightweight and portable. | Tracks are typically sold separately. |

| Forms straight cuts with minimum effort. | Difficult to use without the track. |

| Suitable for cutting through large MDF sheets, plywood and similar boards. | Requires a long flat surface for the track to sit on. |

| Ideal for cutting kitchen worktops and making sink cutouts. | |

| Cuts at angles up to 48°. |

20. Chainsaw

You need a chainsaw if you’re lopping branches and cutting down trees.

Chainsaws have a set of sharp teeth linked together, which run along a guide bar in one direction. When fitting the chain, ensure it’s pointing the right way, which is usually indicated on the guide bar.

When buying a chainsaw, you must choose between an electric or petrol model. Electric models tend to have shorter guide bars (350–400mm), which is enough for most jobs around the garden. Petrol models are more powerful, but you must refill the tank and prime the engine whenever you want to use it.

| Pros | Cons |

|---|---|

| Cuts through large sections of wood easily. | Heavy, noisy and dangerous. |

| Ideal for site clearances and cutting up firewood. | Beware of nails as they blunt the teeth. |

| Starting the motor can be a pain on petrol models. |

21. Panel Saw

If you have a lot of panels to cut, this is the best saw for the job.

You’ll often find panel saws in DIY stores as they’re used to cut large wholesale sheets into smaller pieces for customers. If a project requires specific lengths or widths, this saw does the job quickly, accurately and safely. Also, most panel saws have a built-in vacuum to extract dust as you cut.

The best thing about vertical panel saws is that they’re much easier to work with than a horizontal table saw when cutting large sheets. The one shown above is an Elcon DSX available from Daltons Wadkin.

| Pros | Cons |

|---|---|

| Ideal for large sheets of plywood, MDF or chipboard. Can cut non-ferrous metals. | Too large for the average DIY workshop. |

| Safer than a horizontal table saw for large pieces. | It cannot make angled cuts. |

Types of Saws — Final Thoughts

Unless you’re a professional with a large workshop, it’s doubtful you’ll need every saw on this list. Most of us only need a handful of these saws.

If you’re serious about getting into carpentry and joinery work, I recommend investing in the following 7 saws:

- Circular Saw

- Mitre Saw

- Table Saw

- Jigsaw

- Reciprocating Saw

- Traditional Handsaw

- Hacksaw

Of course, the saws you need depend on your projects, but the list above is a good starting point and covers most of the jobs you will likely undertake.

Pro Tip: For a detailed look at commonly used hand saws, check out the video below by Paul Sellers.